Electrically speaking, a permanent magnet DC motor can be modelled as follows:

applying LKT we obtain the following differential equation

$$v = Ri+L\frac{di}{dt}+e$$

where $R$ is the equivalent resistance of the brushes plus the windings, $L$ is the inductance as seen from the external terminals of the motor and $e$ is the back EMF. Usually R is very small and can be difficult to measure with a multimeter. The back EMF can be expressed as a function of the speed of the motor $e = k\phi\omega$.

Mechanically speaking, the motor can be modelled by considering the following equation:

$$J\frac{d\omega}{dt}=C_e-C_r=k_1\phi i - C_r(\omega)$$

The torque of the motor $C_e$ depends linearly with the current since the flux is constant (permanent magnet generate a constant flux). The opposing torque usually is constant, but in general may be a function of the angular speed of the rotor (think of friction for instance). If we put together these two differential equation, we find the following system:

$$\left\{\begin{matrix}

\frac{di}{dt} = -\frac{R}{L}i- \frac{k \phi}{L}\omega + \frac{v}{L}

\\

\frac{d\omega}{dt}=\frac{k_1\phi}{J}i - \frac{C_r(\omega)}{J}

\end{matrix}\right.$$

then, assuming the relationship between $C_r$ and $\omega$ is linear, the following system can be built

$$\frac{d}{dt}\begin{pmatrix}

i

\\

\omega

\end{pmatrix}=\begin{pmatrix}

-\frac{R}L{} & -\frac{k \phi}{L}\\

\frac{k_1 \phi}{J} & -k_f

\end{pmatrix}

\begin{pmatrix}

i

\\

\omega

\end{pmatrix} + \begin{pmatrix}

\frac{v}{L}

\\

-C_{r_0}

\end{pmatrix}$$

The variable of interest is the angular speed of the motor, therefore

$$y = \begin{pmatrix}

0 & 1

\end{pmatrix}\begin{pmatrix}

i

\\

\omega

\end{pmatrix}= \omega$$

Now the system has been transformed in the canonical state

$$\frac{d}{dt}\bar{x} = \bar{A} \bar{x}+ \bar{B}\bar{u}$$

$$\bar{y} = \bar{C}\bar{x} + \bar{D}\bar{u}$$

Using Matlab we can simulate the system response to a unit voltage step. Note that I’m assuming the torque of the mechanical load is constant in this case.

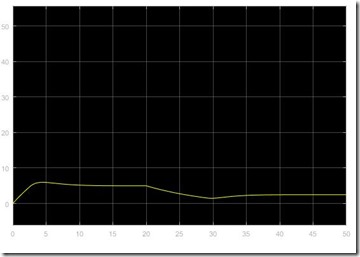

As you can see in the comments in the code, the final state of the system can be calculated just by setting every derivative to zero and then solving for the state variables. In this case it turns out that by applying a unit voltage step, the motor is absorbing 0.2 A and turning at a speed of 45.8 rad/s. You can take a look at the transient of the angular speed variable in the graph below

This is a nice result but we can’t really control the motor. I mean, we can vary the voltage and then get a certain speed as output but in most cases we need a certain speed regardless of the voltage (provided it is within the nominal voltage). In the second part of the code, I decided to put a PI regulator in series with the system and then use negative feedback to control the speed of the motor. Now we can set as an input a certain speed and see how the motor behaves in the transient. By requiring the motor to reach a speed of 1 rad/s, this is the transient that follows:

You can immediately notice that the motor took less time to get up to the required speed compared to the previous case. Why is this happeing? This is happening because by inserting a regulator and negative feedback the poles of the system (and therefore its dynamic behaviour) have been changed.

Modelling a DC motor with Simulink

Simulink, quote, “is a graphical programming environment for modeling, simulating and analyzing multidomain dynamic systems”. Simulink was made for simulating dynamic systems and it is particularly useful whenever you need to simulate models described by differential equations. You may, legitimately, ask why use Simulink? A DC motor is very simple, I can use other tools or even just pen and paper to find out the solution to my questions. I think the advantage of using Simulink is that it allows you to simulate different scenarios and complex models in a very short time. In our example we are simulating a DC motor, but think of a parallel of synchronous generatos, what if you’d like to simulate what happens in case of a short circuit at a specific point in a branch of the transmission line? Let’s see some more interesting simulations on the DC motor. The raw model of the DC motor can be modelled as follows

The model can then be wrapped in a subsystem and then used within other models. For example, let’s simulate a short circuit. In the following example the motor is started at time 0 with a 24 V step. At 60 seconds, a short circuit happens, the voltage on the motor terminals becomes zero. What would you expect the current to do? Let’s find out. We apply a 24 V step voltage to the motor, let it reach the equilibrium and then apply a short circuit! This is the Simulink model

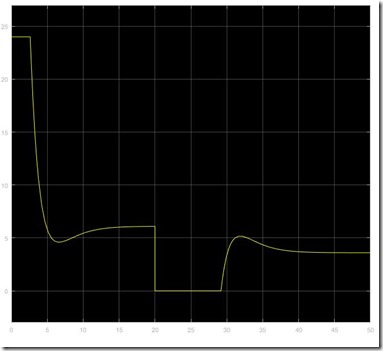

If we take a look at the first scope, we find out that the current has the following behaviour:

Current as a function of time [A]

Note that initially the current is limited only by the resistance of the windings which is very low, therefore a big current spike of about 4.36 A (which is exactly equal to 24V / 5.5 Ohms) follows the application of the voltage. If you were powering this motor directly from a solar panel for instance, you might run into trouble at the startup since the panel may not be able to supply the current required at startup. Batteries can usually do that but always check the data sheet to be sure. Then, as the speed increases, the back EMF increases as well reducing the current through the windings. For everyone that is familiar with RL circuits, this overall behaviour might seem odd at a first glance: at 60 seconds the short circuit occurs and the current seems to jump immediately to a minimum negative value. However, if we zoom in the milliseconds range, we can easily find out the typical behaviour of an RL circuit. The current changes accordingly to the time constant of the motor which is about 0.5 ms. This means that the current will be practically constant after about 2 ms. This is exactly the behaviour we find out in the graph below.

Detail of the current behaviour in the millisecond time scale [A]

What is the reason behind this behaviour? The first graph shows the current’s behaviour for times much larger than the L/R time constant. Since the mechanical time constant is much larger than the electrical one (the mechanical time constant should be about 10 seconds, judging from the graph) in the first milliseconds of the transient, we could assume that the angular speed is constant and neglect completely the mechanical behaviour. Another interesting thing to notice is that when the short circuit happens the current becomes negative, this means that the current starts to flow in the opposite direction. This is understandable since now there is nothing opposing the back EMF which depends only on the angular speed. If you look closely at the end of the transient, the current becomes positive again: since the resistant torque is supposed constant, when the motor reaches a speed of zero, it continues to accelerate until the electromagnetic torque equals the resistant torque (0.1 Nm). The back EMF changes sign (it becomes negative) and therefore the current changes sign as well (it becomes positive again). In practice this behaviour can be found, for example, in a DC motor used for pulling an object up to a structure. As soon as the short circuit happens the force of gravity pulls the object back to earth and the “resistant torque” applied is almost constant. This is obviously not the case of an electric motor of a car: in that case the motor will simply stop due to friction and other losses which basically depend, to some extent, on the speed.

In our example, at the equilibrium after the short circuit, the current is 0.2 A and the speed is 2.2 rad/s (in the opposite direction with respect to the initial speed). The terminals of the motor are shorted, no current is pumped into the supply, but the mechanical load is supplying 0.1 * 2.2 = 0.22 W of power. Where is that power going? Simple, it is being dissipated as heat by the windings since 5.5 * 0.2^2 = 0.22 W exactly as expected.

Controlling the motor with a PI controller in Simulink

What if we’d like to control the motor speed directly as we did in the Matlab code in the introduction? Well we’ll just implement the control loop in Simulink then:

Note that:

- A PI controller has been connected in series to the system. The PI controller takes as input the error (the difference between the set point and the actual angular speed) and outputs the voltage to apply to the motor.

- In order to make the simulation more realistic, the output of the PI regulator has been constrained to the 0-24V range.

- The set point changes as follows: at time 0s the set point equals 10 rad/s, at time 20s it jumps to 5 rad/s.

If we take a look at the physical quantities we find the following behaviour:

Angular speed [rad/s]

Back EMF [V]

Current [A]

As you can see from the first graph, the system is now much quicker in its response, the equilibrium is reached in about 15 seconds (previously, 60 seconds were needed). This increase of response time, however, is characterized by a bit of overshoot, in fact the speed exceeds the set point and then gets back to it. This can be avoided by fine tuning the PI controller further. This overshoot is reflected in the current’s behaviour.

PID: actual applied output voltage [V]

PID: theoretical applied voltage [V]

Perhaps the output of the PI controller is more interesting. Initially, and at the time the set point is changed, the PI controller would like to apply a very high voltage, as high as about 55 V. Assuming the supply is capable of applying such a voltage, this could damage the motor, a saturation block is used to prevent this problem.

Adding a PWM control to the control loop

It is often the case that many hobby projects use PWM control for DC motors. Say no more, we can simply add a PWM block to our simulation. Well, in this case the “simply” part is not true. I had to think a bit on how to make this subsystem, but it was worth it. The PWM subsystem is shown below above the new control loop

PWM Subsystem

Control loop of a DC motor with a PI controller and PWM

The angular speed seems smooth as you would expect, while the PWM output is fine except that it is, obviously, a bit messy to look at

Angular speed [rad/s]

PWM voltage applied to the motor [V]

I hope you enjoyed this overview of control loops and DC motors. I had these models in my computer for a long time. You can download all the Simulink files here if you wish to tweak and tinkle with them.

Great!

ReplyDeleteThanks!

DeleteAs we know there are many companies which are converting into Big Data Implementation Services with the right direction we can definitely predict the future.

ReplyDeleteI at last discovered extraordinary post here.I will get back here. I just added your blog to my bookmark locales. thanks.Quality presents is the vital on welcome the guests to visit the page, that is the thing that this website page is giving.Data science course in malaysia

ReplyDeleteI think this is the minimum value to earn more than just commitdata science course in delhi

ReplyDeleteStandard visits recorded here are the simplest strategy to value your vitality, which is the reason why I am heading off to the site regularly, looking for new, fascinating information. Many, bless your heart!hrdf training course

ReplyDeleteI think I have never watched such online diaries ever that has absolute things with all nuances which I need. So thoughtfully update this ever for us.

ReplyDeletePMP

ReplyDeleteNice work... Much obliged for sharing this stunning and educative blog entry!

hrdf claimable training

I recently came across your article and have been reading along. I want to express my admiration of your writing skill and ability to make readers read from the beginning to the end. I would like to read newer posts and to share my thoughts with you.

ReplyDeletebusiness analytics course

Welcome to an incredible gathering here you will pick up every little thing about me

ReplyDeletedigital marketing course in delhi

I find your opinion quite interesting, but the other day I stumbled upon a completely different advice from another blogger, I need to think that one through, thanks for posting.

ReplyDeletecertification on data analytics

I find your opinion quite interesting, but the other day I stumbled upon a completely different advice from another blogger, I need to think that one through, thanks for posting.

ReplyDeletecertification on data analytics

This post is very simple to read and appreciate without leaving any details out. Great work!

ReplyDeletedata scientist certification

I can't recall the last time I enjoyed an informative article like I have yours. You've exceeded my high standards and expectations with your excellent writing skills. You must have higher standards than I do.electrician near me

ReplyDeleteReading this material made me think. It's really full of useful and interesting facts that anybody can grasp. I enjoyed this article. You have some real quality information that appears to be researched well. I agree with a lot of your viewpoints. emergency electrician

ReplyDeleteGood information you shared. keep posting.

ReplyDeletemachine learning training in aurangabad

تصميم مواقع

ReplyDeleteتصميم-مواقع

تصميم-المواقع-الاخبارية

افضل-شركة-تصميم-مواقع-في-السعودية

تصميم-المواقع-الإلكترونية

تصميم-موقع-انترنت

تصميم-مواقع-طبية

I truly like you're composing style, incredible data, thankyou for posting.

ReplyDeletedata science course

Good information you shared. keep posting.

ReplyDeleteai courses in aurangabad

Nice Blog! such a informative things you are sharing

ReplyDeleteAngular Training in Pune

very informative thank you for sharing

ReplyDeleteDpi For Web

Neil And Roo offers a great scope of shoe socks for baby boys in the UK, combining charming plans with a cozy fit to keep those tiny toes warm and classy. shoe socks for baby boys in uk

ReplyDeleteMathematics Assignment Help dedicated to providing thorough assistance to ensure the successful completion of your university assignments, aiming for an A+ grade.

ReplyDeleteFINTECHZOOM provides the latest news about Financial Markets, Stocks, Dow Jones, Nasdaq, Commodities, Loans, Mortgages, Crypto and Banking How much money i spent on league

ReplyDeleteWhat a great post! You always know how to break things down so well. Sustainable construction Dubai

ReplyDeleteWhen it comes to choosing the best trading platforms for beginners, WinproFX stands out as a user-friendly and feature-rich option. New traders often struggle with complex interfaces and overwhelming market data, but WinproFX simplifies the process with its intuitive design and educational resources. The platform provides seamless navigation, real-time market insights, and automated trading tools that help beginners make informed decisions. Additionally, WinproFX offers a demo trading account, allowing new traders to practice strategies without financial risk. With competitive spreads and fast execution speeds, it ensures a smooth trading experience for those just starting their journey in the financial markets.

ReplyDeleteBest Forex Trading Platform in India-

Brilliant post! Informative and well-structured. Looking forward to more of your content! 💡📚

ReplyDeleteThe creative world is undergoing a seismic shift, and at the epicenter of this transformation is Generative AI.Fashions mag

ReplyDeleteI had a good time reading this — your writing always feels like a friendly conversation. Biobitesolutions

ReplyDeleteReally enjoyed the flow of the content. Very engaging. Haarausfall nürnberg

ReplyDeleteCustomized WordPress Website Development Services in Delhi

ReplyDeleteCustomized WordPress Website Development Services in Delhi

Customized WordPress Website Development Services in Delhi

Customized WordPress Website Development Services in Delhi

Customized WordPress Website Development Services in Delhi

Customized WordPress Website Development Services in Delhi

Customized WordPress Website Development Services in Delhi

Customized WordPress Website Development Services in Delhi

Customized WordPress Website Development Services in Delhi

Customized WordPress Website Development Services in Delhi

Website Design & Development Services in Delhi

ReplyDeleteWebsite Design & Development Services in Delhi

Website Design & Development Services in Delhi

Website Design & Development Services in Delhi

Website Design & Development Services in Delhi

Website Design & Development Services in Delhi

Boost Your Online Presence with Expert Website Design & Development in Delhi

ReplyDeleteBoost Your Online Presence with Expert Website Design & Development in Delhi

Boost Your Online Presence with Expert Website Design & Development in Delhi

Boost Your Online Presence with Expert Website Design & Development in Delhi

Boost Your Online Presence with Expert Website Design & Development in Delhi

Boost Your Online Presence with Expert Website Design & Development in Delhi

Boost Your Online Presence with Expert Website Design & Development in Delhi

Boost Your Online Presence with Expert Website Design & Development in Delhi

Boost Your Online Presence with Expert Website Design & Development in Delhi

Boost Your Online Presence with Expert Website Design & Development in Delhi

DoorbellMount.com is an online shop specializing in custom, 3D-printed doorbell mounts and brackets. Designed and manufactured in Louisiana by a seasoned mechanical engineer with 25 years of experience, the site offers tailored solutions for virtually any doorbell brand and mounting scenario.Doorbell

ReplyDeleteA doorbell is an electric or wireless signaling system that produces sound when a button is pressed at the entrance.Doorbell

ReplyDeleteA food with a rich history. The word "jerky" comes from the Quechua word ch'arki, meaning "dried, salted meat." Its origins can be traced to indigenous peoples in the Andes and North America who used this method to preserve meat for long-term storage and travel.Jerky

ReplyDeleteWith Houston’s busy traffic, drivers benefit from competitive auto insurance rates and discounts for safe driving.Insurance Houston

ReplyDeleteGreat point on BIS for import! It's a non-negotiable step for legal market access in India. Navigating the process is crucial to avoid customs delays and penalties. An Agile Regulatory mindset is essential for seamless compliance.

ReplyDeleteFundedfirm stands as a leading forex prop firm in India for 2025, providing traders a seamless access point to real trading capital via its efficient and transparent one-step evaluation process on the cutting-edge MetaTrader 5 platform. Known for its lightning-fast execution, advanced charting tools, and broad array of forex pairs, commodities, and indices, Fundedfirm is perfectly suited to meet the evolving needs of Indian forex traders. The one-step evaluation challenges traders to achieve profit targets between 8-10% while enforcing strict daily and overall drawdown limits, fostering disciplined trading and robust risk management skills. Upon successful completion of the evaluation, traders earn funded live accounts backed by genuine capital, granting the freedom to employ a variety of trading strategies including scalping, swing, and news trading, with the flexibility to hold positions overnight or during critical economic events. Fundedfirm supports quick deposits and withdrawals through popular Indian payment methods like UPI and bank transfers, with payouts usually processed within 24 hours for rapid access to profits. Competitive profit splits starting at 90%, low commissions, and clear, transparent policies create an ideal environment for traders at all levels. Backed by comprehensive educational resources and responsive customer service, Fundedfirm empowers Indian traders to build sustainable and profitable trading careers and thrive in the dynamic prop trading landscape of 2025.

ReplyDeleteForex prop firm in India

Smart Doorbell: A modern upgrade featuring video, motion detection, and app connectivity for real-time monitoring and security.Doorbell

ReplyDeleteBespoke Iron On Patches Wholesale Custom Quality at Affordable Prices Looking for wholesale bespoke iron on patches that don’t compromise on quality? We create custom embroidered patches that apply easily with heat and stay put for good. Ideal for fashion brands, schools, and corporate gifts, with flexible bulk pricing and USA-based support. rush patch dot com

ReplyDeleteForex Trading for Beginners Online is an easy and accessible way for new traders to learn how the global currency market works and start trading from anywhere. Beginners can use online platforms like MT4, MT5, and web-based trading apps to practice with demo accounts, understand currency pairs, and learn basic strategies without risking real money. Online resources, tutorials, and market analysis help new traders gain confidence and improve their skills. With the right guidance, risk management, and a trusted broker, beginners can gradually build their knowledge and start trading Forex safely and effectively.

ReplyDeleteContact us Address – 1st Floor, The Sotheby Building, Rodney Bay, Gros-Islet, SAINT Lucia P.O Box 838, Castries, Saint Lucia Phone no – +97144471894 Website – https://winprofx.com/

Their River Oaks Cars website is well-organized and easy to navigate, giving visitors a clear overview of their full vehicle lineup and services.

ReplyDeleteThe Zero-Down Car Leases page is useful for shoppers interested in minimizing upfront payments while accessing new vehicles.

Their Used Vehicle Inventory showcases a wide range of cars, SUVs, and trucks, making it easier for buyers to find vehicles that fit different budgets.

For truck enthusiasts, the New RAM Trucks section highlights powerful, work-ready pickups.

Those looking for pre-owned trucks can explore the Used RAM Inventory for reliable, durable options.

Jeep fans will find value in the Used Jeep Inventory, which features SUVs suitable for both city driving and off-road adventures.

The New Vehicle Inventory page covers all their brand-new cars, giving buyers variety across models and body styles.

Finally, the Mopar Service Center provides maintenance and repair services using genuine parts and certified technicians, important for long-term vehicle care.

Their Alfa Romeo of Houston website is user‑friendly and well organized, making it easy to explore the dealership’s vehicle lineup and services.

ReplyDeleteThe New Alfa Romeo Inventory page showcases a variety of current models, helping visitors compare options in one place.

On the Alfa Romeo SUV Inventory page, users can explore luxury SUV choices that combine style with performance.

The Alfa Romeo Giulia page highlights a sporty and elegant sedan option, useful for buyers researching performance and design.

Their Alfa Romeo Stelvio section outlines the blend of SUV practicality and dynamic driving characteristics.

Finally, the Alfa Romeo Tonale page presents a compact luxury SUV choice, ideal for those seeking efficiency without compromising on features.

Their Helfman Imports website is well laid out and easy to navigate, providing a good overview of Maserati’s luxury lineup and dealership services.

ReplyDeleteThe Maserati Ghibli page highlights this sporty luxury sedan, offering insights into its performance and refined design.

On the Maserati Quattroporte page, visitors can explore details about this flagship executive sedan, known for elegance and performance.

The Maserati MC20 section showcases the brand’s high‑performance supercar, combining cutting‑edge engineering with dramatic styling.

Their Maserati GranCabrio page outlines this luxurious convertible — great for those interested in open‑air performance driving.

On the Maserati GranTurismo section, users can find information about this classic grand tourer, blending comfort and speed.

The Maserati Levante page presents the brand’s luxury SUV offering, with insights into its design, capability, and premium features.

Their 1Click Auto Auction website offers a clear overview of their platform and makes it easy to browse different vehicle categories.

ReplyDeleteThe Used Cars Under $5,000 in Austin section highlights affordable options for budget-conscious buyers or first-time drivers.

On the Used Cars Under $10,000 page, visitors can review a wider range of reasonably priced vehicles that balance cost and practicality.

Their Under $12,000 listings expand on that selection, presenting options with slightly newer models and solid mileage.

The Under $15,000 section further broadens choices with additional sedans, SUVs, and mid-range vehicles.

For those open to a higher budget, the Under $20,000 page offers access to potentially newer and better-equipped cars.

Their ZenLite Pro website provides a clear overview of their platform and tools, with an easy-to-navigate layout that helps visitors quickly understand what services they offer.

ReplyDeleteTheir SafeHaven Trade website presents a clear overview of their platform and tools designed for crypto traders of various experience levels.

ReplyDeleteThe Crypto Trading Simulator for Power Users page focuses on advanced simulation features tailored to experienced traders wanting to refine strategies in a risk-free environment.

On the Crypto Trading Simulator for Newcomer Navigators page, beginners can explore foundational tools and guided scenarios to build confidence before trading live.

Their Crypto Trading Simulator for Crypto Rebooters section highlights a simulator designed for traders returning to the market who want to re-learn and test their skills without financial risk.

ReplyDeleteTheir 680 Unsecured Loans website provides a general overview of unsecured loan concepts and information that can help users better understand different types of financing.

The Personal Loans in Texas page outlines common considerations and factors for individuals researching personal loan options in that region.

On the Business Loans in Arizona section, visitors can review general details related to small business financing and typical borrower requirements.

Their Business Loans in Texas page offers information relevant to entrepreneurs and businesses exploring financing solutions within the Texas market.

The Personal Loans in Arizona page explains general personal loan topics as they relate to borrowers in Arizona.

Finally, the Business Loans in Florida section presents broad insights into financing considerations for Florida-based companies.

Their ChemoDynamics website gives an overview of the company’s scientific services and capabilities in chemical research and development.

ReplyDeleteThe CRO Services page explains the contract research support they can provide, outlining laboratory testing and analysis functions that researchers might consider when planning projects.

On the CMO Services section, the site details contract manufacturing support, highlighting processes and production capabilities relevant to scale-up or synthesis workflows.

Their Additional Capabilities page presents extra technical and scientific resources the organization offers, which can help users get a broader sense of their research and development support services.

Educational & Community Support: Online sellers often provide resources, forums, and customer support to help owners understand parrot behavior, diet, and training, fostering a responsible and informed pet ownership experience.Buy parrots online

ReplyDeleteChoosing the best online forex brokers is essential for successful currency trading, as they provide the gateway to the global foreign exchange markets. Top brokers offer competitive spreads, fast execution speeds, robust trading platforms, and strong regulatory oversight to ensure a secure and transparent trading experience. They also provide educational resources, responsive customer support, and advanced tools for market analysis, making them suitable for both beginner and experienced traders. By selecting a reliable and reputable online forex broker, you can trade with confidence, manage your risks effectively, and seize opportunities in the dynamic world of forex trading.

ReplyDeleteContact us Address – 1st Floor, The Sotheby Building, Rodney Bay, Gros-Islet, SAINT Lucia P.O Box 838, Castries, Saint Lucia Phone no – +97144471894 Website – https://winprofx.com/

A Free Funded Forex Account gives traders the opportunity to trade real capital without risking their own money. With this account type, traders can showcase their skills, follow risk management rules, and earn profits while the funding is provided by the firm. It is an ideal option for beginners who want real market experience and for experienced traders who wish to scale their strategies without personal financial exposure. Free funded forex accounts help traders build confidence, discipline, and consistent performance while keeping personal risk to a minimum.

ReplyDeleteContact us Address – 1st Floor, The Sotheby Building, Rodney Bay, Gros-Islet, SAINT Lucia P.O Box 838, Castries, Saint Lucia Phone no – +97144471894 Website – https://winprofx.com/

Join expert-led Pega classes designed for job-oriented learning.

ReplyDeleteConcepts are explained using real-time use cases.

Assignments and labs enhance skill development.

Great option for guided learning.

A full stack Python developer course teaches complete application development.It focuses on frontend and backend.This full stack Python developer course supports growth.It is dependable.

ReplyDelete