It turns out the physics behind this mechanism is pretty interesting and easy to code, therefore I thought I could give it a go and try to make a simulation.

First of all we need to define the problem and solve it:

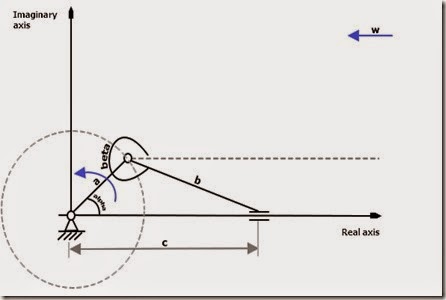

This is the basics from which we start: the crankshaft (rod ‘a’), the connecting rod (rod ‘b’) and the piston whose position is denoted with c. The motion of rod ‘a’ is a pure rotational motion while the motion of rod ‘b’ is somewhat more complex. The piston is performing a linear motion since it is constrained onto the real axis.

Now you might ask yourself why I am using the imaginary plane… It turns out that you can represent each vector (a,b and c) with a complex number, and this semplifies our problem into a more manageable system of two equations.

By using vector properties we can easily write:

The vector equation above states that the position of c is the sum of a and b as it can easily be seen on the picture. Now, we can get our real and imaginary coordinates in the plane by using Euler’s formula:

Note that every one of these parameters is a function of time and assuming that alpha(t), the length of the rods a and b are known, the system can be solved for c and beta. Furthermore by deriving the original equation we can obtain velocity and acceleration for each time t, since assuming alpha(t) is known then the derivatives of alpha(t) are known too (assuming alpha is derivable two times with respect to t).

Here are velocity and acceleration (vectors), respectively:

Now, for the sake of this example, I am assuming

Given my assumption,

Ok, so far so good, now that we have the position at each time we just need to translate everything in a language that Python can understand: I used a class, however you can easily avoid using it since it is not really necessary

Once we have coded all what is above, we can create a My_mechanism instance and call the methods, be sure not to call all the methods at once since it will not run them all. Call a method at each time:

Here below are the videos I made using the animations of the mechanism:

Hope this was interesting.

Code an full connecting rod design in MATLAB or C program

ReplyDeletewhere the input parameters are

Crank Length, crank radius , crank angle, bore , max. explosion pressure (Pmax).

The output should be

Load on the piston ( Gas Load + inertia load)

Crank Length / Crank radius ratio

Big End dimensions

Small End dimensions

Dimensions of Web

Total Force on bolts and cap

Root area of bolt

Thickness of big end cap

State your assumptions and post the code and try to plot

Thank you

Nice post. Thanks for sharing...

ReplyDeleteseo training institute in bangalore

Great Article bcom colleges Bangalore is home to some of the best B.Com colleges, offering high-quality education and a variety of specializations that cater to the needs of aspiring commerce students. These colleges provide a strong academic foundation, combined with modern infrastructure and experienced faculty, to help students excel in their careers. Institutions like Christ University, St. Joseph's College of Commerce, Jain University, and Mount Carmel College are known for their rigorous curriculum, industry exposure, and excellent placement opportunities. With a focus on holistic development, these colleges prepare students for diverse roles in business, finance, accounting, and entrepreneurship, making them an ideal choice for anyone looking to pursue a B.Com degree in Bangalore.

ReplyDelete